Andrews Fasteners Limited

The Fasteners Specialist

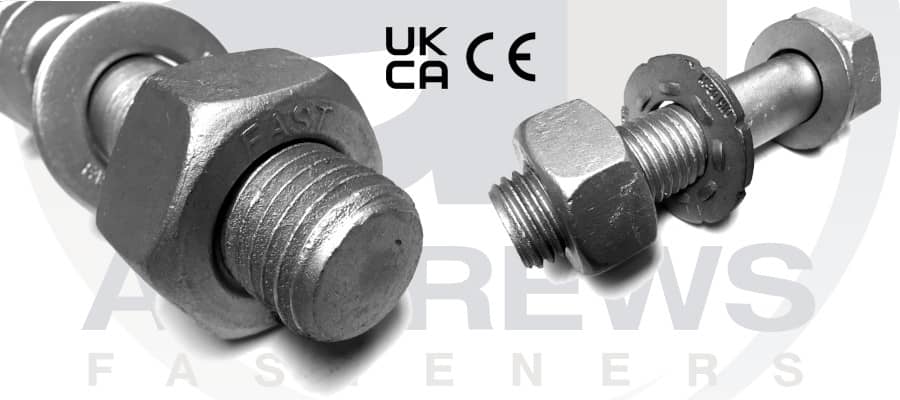

Andrews Fasteners supply quality assured CE & UKCA approved fasteners to various industries at competitive prices.

Andrews Fasteners reputation for quality assured fasteners is the foundation on which the company stands. Our quality systems are independently assessed, certified and approved to BS EN ISO 9001:2015, NHSS3 (National Highway Sector Scheme 3) and CPR (Construction Product Regulation) for:

- BS EN 15048 Non-preloaded structural bolting assemblies (SB) – CE & UKCA marked

- BS EN 14399 High-strength structural bolting assemblies for preloading (HR and HV) – CE & UKCA marked

Innovative company

Andrews Fasteners innovations have revolutionised how bolts are packaged, presented and delivered to Construction Companies UK and Worldwide. Our company is the originator of the Colour Coded Bag system used today.

Quality & Control

Quality is our priority, this is why all our products are tested at our in-house facility before they are released to our customer. Andrews Fasteners in-house testing procedures include:

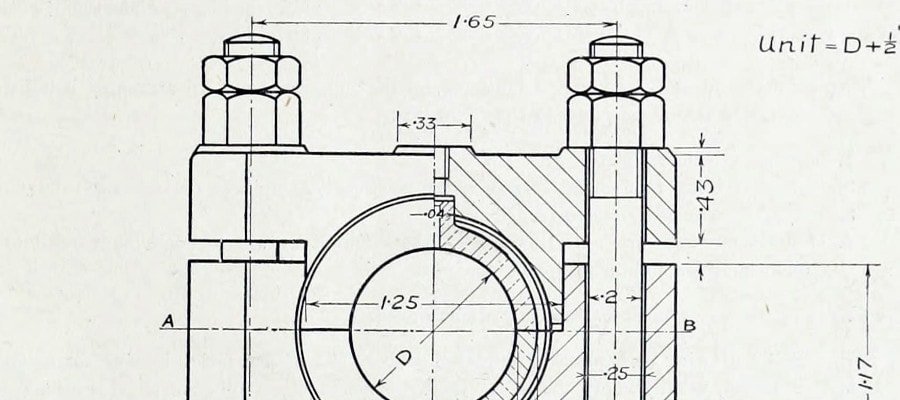

- Dimensional checks including internal and external thread (gauges)

- Plating checks (surface coating – finish)

- Core and Surface hardness checks (Leeb & Rockwell C)

- Tensile, Wedge and Proof Load tests

- Bend and Compression tests

- Assembly – Suitability tests to BS EN 15048-2 & BS EN 14399-2

Our achievements

- Andrews Fasteners is approved to ISO 9001 and NHSS3 (National Highway Sector Scheme 3);

- We hold UKCA & CE approval certificates for BS EN 14399 and BS EN 15048 bolt assemblies;

- Our partner factories worldwide enables us to manufacture and stock a large number of assembled products for global supply;

- We are able to supply containers directly from factory;

- 3.1 Test Certificates are supplied for most of our products;

- Products are fully traceable from our manufacturers;

- Your company can always count on our technical expertise and advice;

- We are able to provide various Corrosion Resistant finishes;

- Partnering experience with many leading companies gives us the necessary knowledge to offer your company essential support.