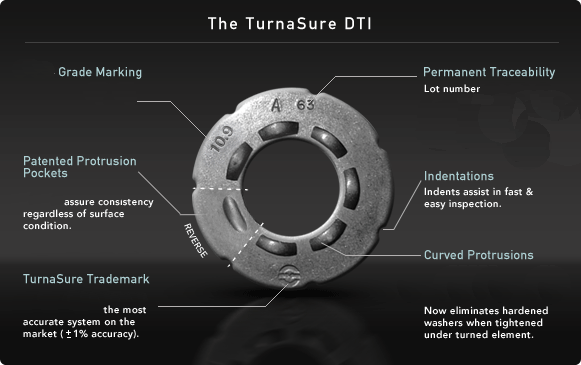

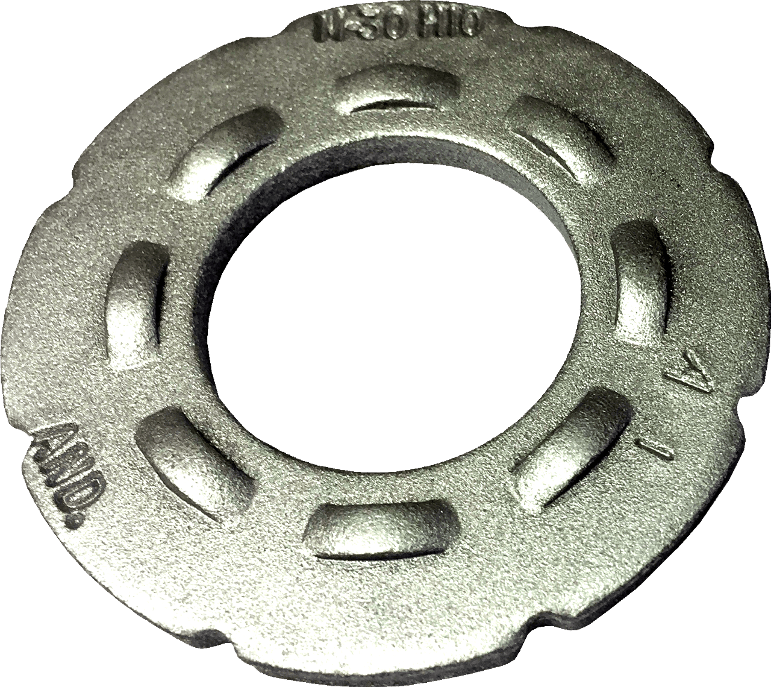

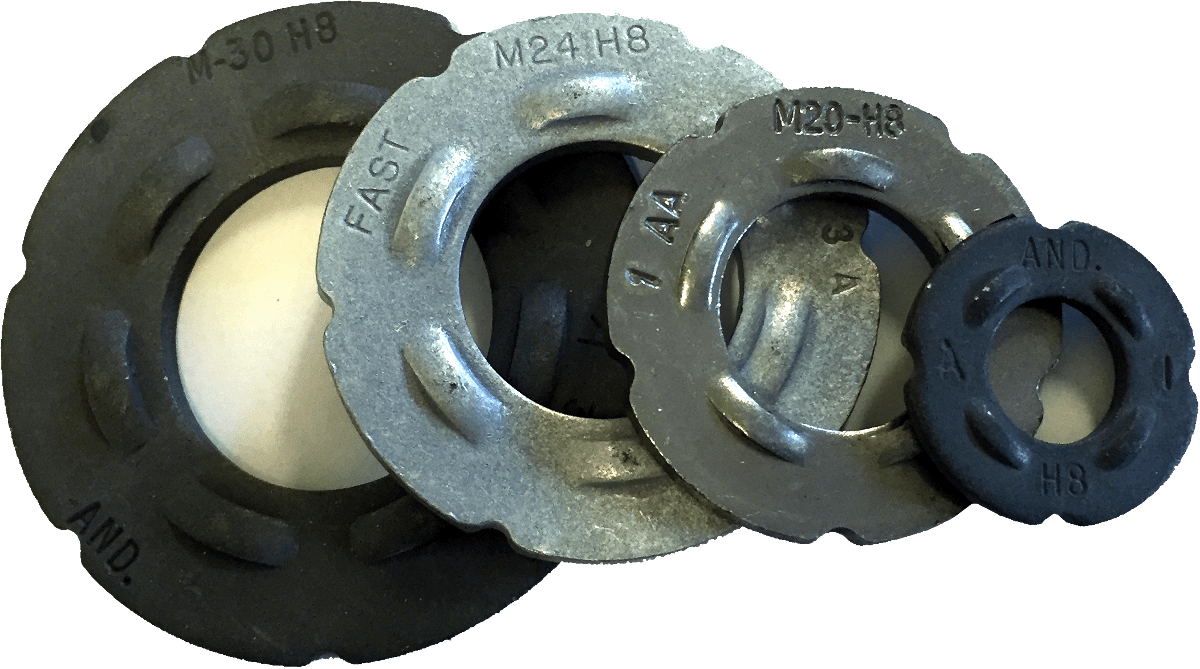

Andrews Fasteners company in manufacturing Direct Tension Indicators Washers (DTI Washers) in well know in construction industry company based in United States – TurnaSure. All our washers are marked with our headmark FAST (previously AND.).

Benefits of using Direct Tensions Indicators Washers:

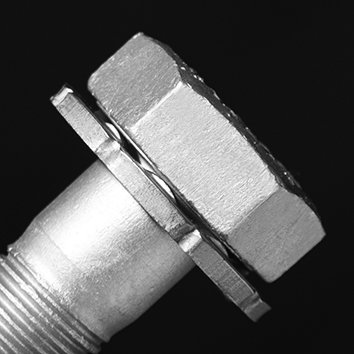

- The use of DTIs is the simplest way of ensuring that bolting assemblies are tensioned properly;

- The use of DTIs saves cost on inspection;

- No torque figures are required, only feeler gauges;

- Risk reduction on over tightening;

- DTIs are manufactured in compliance with EN 14399-9 and can be supplied with CE approved preloadbolting assemblies;

- Unique curved protrusion design of Turnasure DTIs reduce necessary of using nut face / bolt face washers for 8.8 grade assemblies;

- Direct Tension Indicators (DTI) retain their accuracy regardless of their surface condition during tightening, be they oiled, coated or even rusted.

- DTIs provide assurance of slip resistance.

Product Range

| Description | Specification | Size range |

|---|---|---|

| Direct Tension Indicators Washers (DTI Washers) | EN 14399-9 Alternative to BS 7644-1, ASTM F959M | M12–M36 |

Finishes available

| Finish | Specification |

|---|---|

| S/C Self Colour | Bare |

| SHER / SHERA Sherardized Vapour galvanising | EN ISO 17668 EN 13811 BS 7371-8 BS 4921 |

| MZP / MG Mechanical Applied Coating (Galvanized/Zinc) | BS 7371-7 ASTM B695 |

For technical information and advice on the use of Direct Tension Indicators Washers supplied by Andrews Fasteners please see our Technical Support Page.