When ordering Preloaded Assemblies (EN 14399-1) to be installed with Direct Tension Indicator Washers (DTIs), there are 4 different methods of how they can be installed. Depending on the access or preference, you may choose one method, over another.

At the purchase stage, we may not know how you will be installing your assemblies. Please read below, as you may require an additional washer(s) to be purchased.

Installation methods:

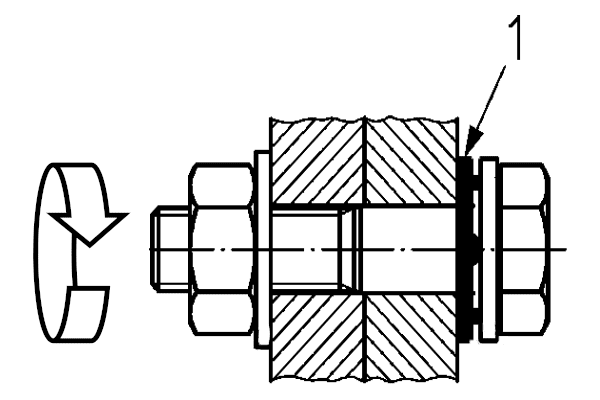

Installing DTI under the bolt head when the nut is rotated (Figure 1)

- when the bolt is Grade 8.8 No extra washer required

- when the bolt is Grade 10.9 Bolt Face Washer (EN 14399-9, Marked HB) required

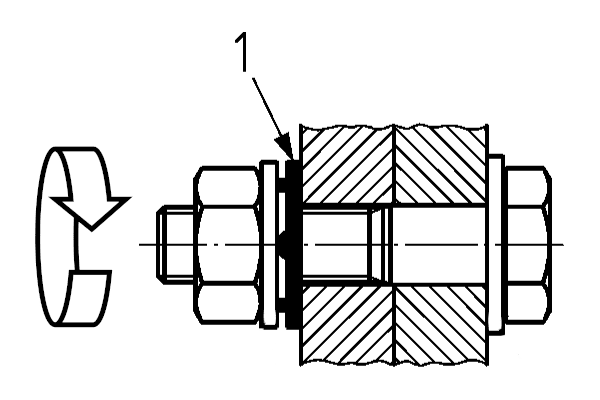

Installing DTI under the nut when the nut is rotated (Figure 2, most common application)

- when the bolt is Grade 8.8 Nut Face Washer (EN 14399-9, Marked HN) required

- when the bolt is Grade 10.9 Nut Face Washer (EN 14399-9, Marked HN) required

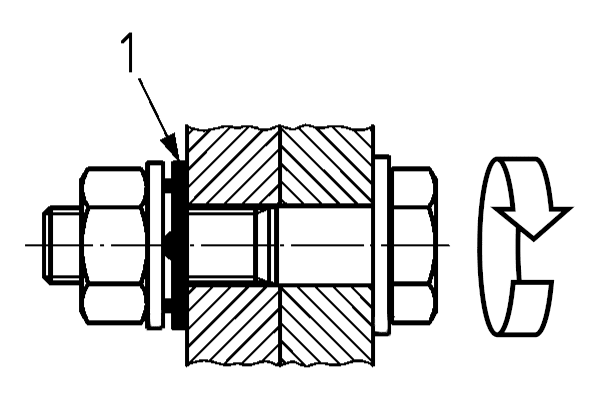

Installing DTI under the nut when the bolt head is rotated (Figure 3)

- when the bolt is Grade 8.8 Nut Face Washer (EN 14399-9, Marked HN) required

- when the bolt is Grade 10.9 Nut Face Washer (EN 14399-9, Marked HN) required

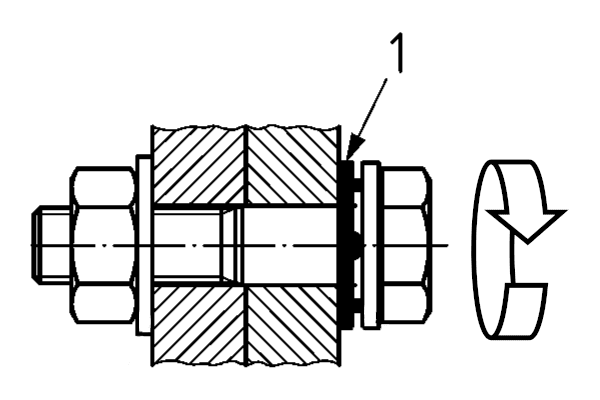

Installing DTI under the bolt head when the bolt head is rotated (Figure 4)

- when the bolt is Grade 8.8 Bolt Face Washer (EN 14399-9, Marked HB) required

- when the bolt is Grade 10.9 Bolt Face Washer (EN 14399-9, Marked HB) required

For more details please refer to:

Shortlink: afast.uk/dti

↫ Go back