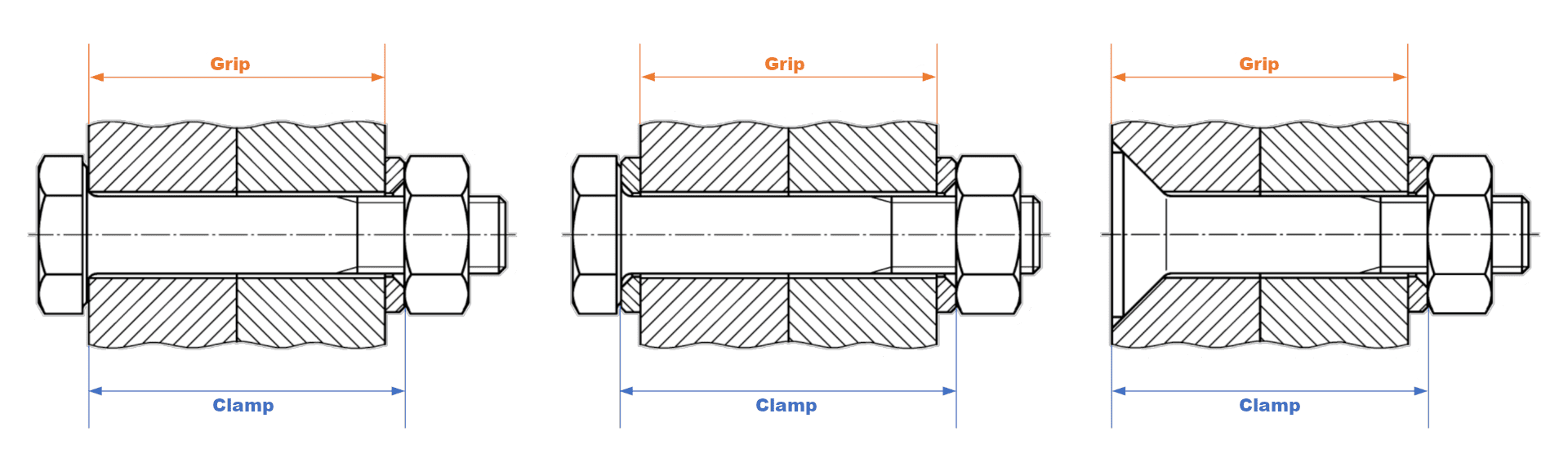

The clamp length is the distance between the bolt head and the nut holding all the components together. It includes steelwork, any shims, plates and washers used.

The grip length is the thickness of the steelwork (that includes plates, shims etc.) that can be gripped together by the bolt and nut assembly. It strictly depends on the specific application (how many washers are used in the assembly).

Example

For EN 14399-3 hexagon bolt assembly type HR, diameter M30 and 100mm in length, the reference clamp length will be between 48mm up to 69mm, whereas the grip length with one washer will be 44-63mm and two washers 40-57mm.

If the total steelwork thickness is 50mm and you are using two washers, the M30x100 bolt assembly is the prefered length that lands between 40mm minimum and 57mm maximum grip length.

The clamp length, 48mm minimum, will provide in the application at least 4-full threads from the shank of the bolt, and 69mm maximum, at least 1-full thread protruding above the face of the nut.

↫ Go back